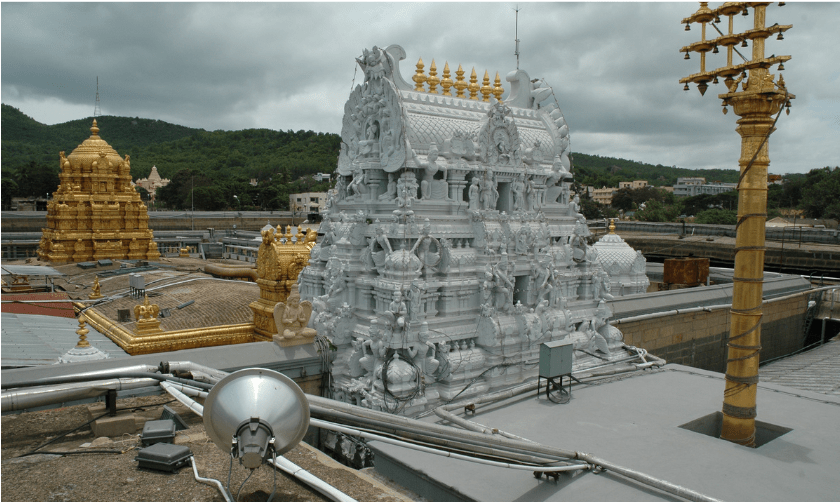

Tirupati temple project case study

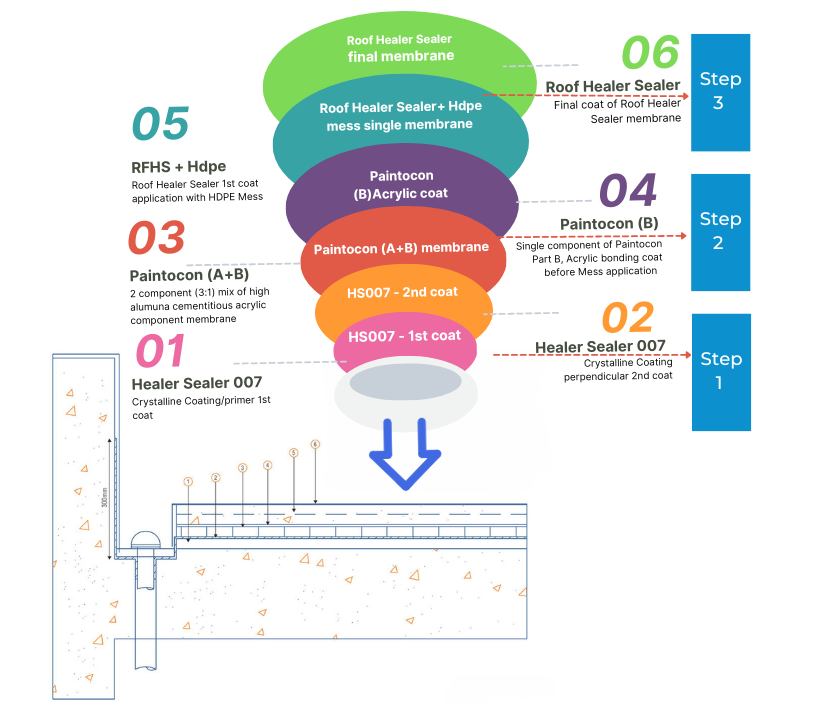

The Thirupati Balaji Main dom and Brahmchari ashram building were huge seepage & leakage issues and problems solves through our advanced Crystalline Roof treatment on right time.

Your construction schedule shorten

Your construction schedule shorten

Your workmanship reduced

Your workmanship reduced

Your repairs & damages cost reduced

Your repairs & damages cost reduced

You are savings when expenses reduces 30%

You are savings when expenses reduces 30%

Permeability & durability increases

Permeability & durability increases

Warranty 10 years minimum

Warranty 10 years minimum

The Thirupati Balaji Main dom and Brahmchari ashram building were huge seepage & leakage issues and problems solves through our advanced Crystalline Roof treatment on right time.

The Yellow Line of Namma Metro is under construction and will form part of the metro rail network for the city of Bangalore, Karnataka, India. The 18.82 km line connects R.V. Road with Bommasandra and is fully elevated with 16 stations. Phase 1 (CSB-Bommasandra) - June 2023; 5 months' time; Phase 2 (RV Road-CSB) - December 2023; 11 months' time.Bangalore Namma metro station waterproofing integrated concrete treatment with Healer Sealer 007 & Roof/Rain Healer Sealer.

Attara Kacheri in Bangalore, India is the seat of the principal bench of the Karnataka High Court, the highest judicial authority in the state of Karnataka. It is a 125 years old, neoclassical red-painted stone and brick building in Cubbon Park, located on Dr. B. R. Ambedkar Road opposite the Vidhana Soudha. Bangalore High court waterproofing roof & concrete treatment with Healer Sealer 007 & Roof & Rain Healer Sealer.

K R Market (Krishnarajendra Market), also known as City Market, is the largest wholesale market dealing with commodities in Bangalore, India since 1928. A new concrete 3-story structure was erected in the 1990s between the two older buildings. KR Market, City market waterproofing treatment through customize design with Healer Sealer 007 & special co-oplymer mix solutions.